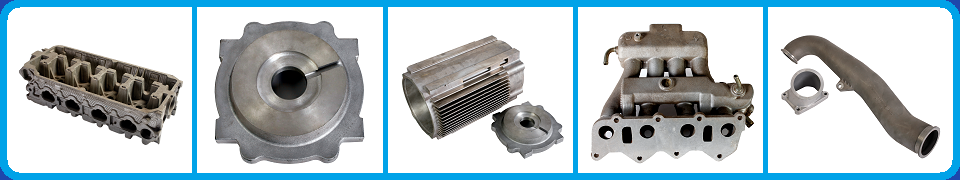

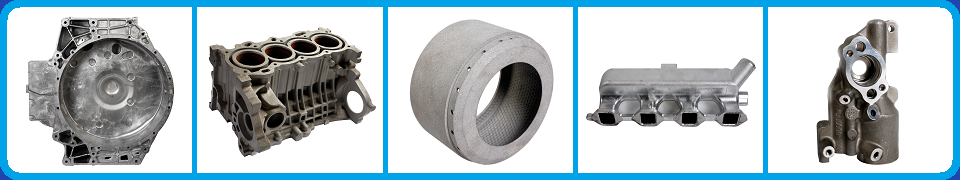

In-house CAD process simulation helps assure superior tooling performance and aluminum casting results. HLJ Casting built up a partnership with HEJIA Tool Limited in October 2011 to meet the needs of “Precision Tools, Perfect Castings.” HEJIA TOOL is dedicated to the manufacture of dies and moulds for aluminum low pressure die casting, gravity die casting, high pressure die casting, grey iron and ductile iron casting, and sand casting. Most of HEJIA’s engineers have more than ten years experience in the tool construction. With HEJIA’s profound experience in die and mould manufacturing, we have earned an enviable position in domestic as well as international arena.

To ensure accuracy and quality, we build the dies and moulds in accordance with the below processes.

- Receive a 3-D CAD model, tooling guidelines and standards

- Compare part print to model to identify discrepancies, and then review and revise as needed

- Complete internal kickoff check sheet

- Develop the preliminary drawing/design

- Offer the drawing/design for client review and receive feedback

- Complete the tool design

- Receive client approval

- Begin tool construction

- Track and report progress of tool construction

- Complete the tool

- Provide sample parts from tool, if required

- Deliver the tool

|

|

|

|