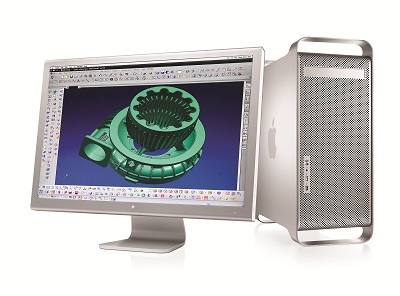

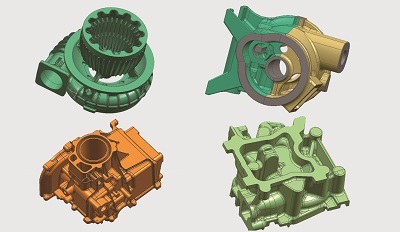

HLJ Casting’s design engineers use computerized modeling to simulate the filling, cooling and expected shrinkage for complex parts. This technique allows for thorough evaluation and refinement of the die and mould design before tool construction begins — and ensures that the tool will produce the best possible part with optimal production efficiencies.

|

|